Final Kit Plane Certification

and Inspection

I found that the prep for the final kit

plane certification was more difficult than the the inspection

itself.

You have to fill out several forms, calculate weight and

balance,

prepare your airplane, and make arrangements for the actual inspection.

Paperwork

All of these documents need to

be completed, and ready for the inspector, in order to complete your

final kit plane certification. The 8130-12 is the

only one that you can't completely finish yourself, because that one

needs to be notarized.

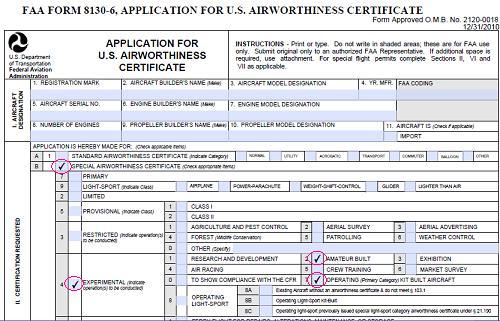

FAA

Form 8130-6

This form was pretty straightforward.

Again, it is important to make sure all the information on each form matches all the

other forms. There are several boxes you should

check. I’ve marked them with the little red circles in the

picture. Download an FAA 8130-6 here(Adobe

pdf file).

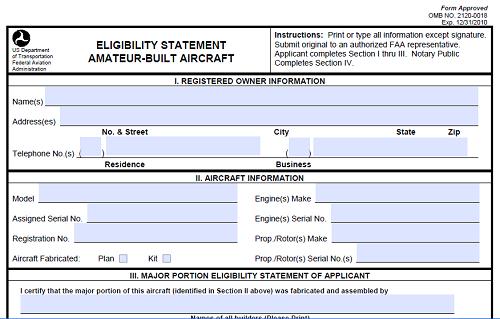

FAA

Form 8130-12

Don’t forget to get this one notarized. Download an FAA 8130-12 here Adobe pdf file).

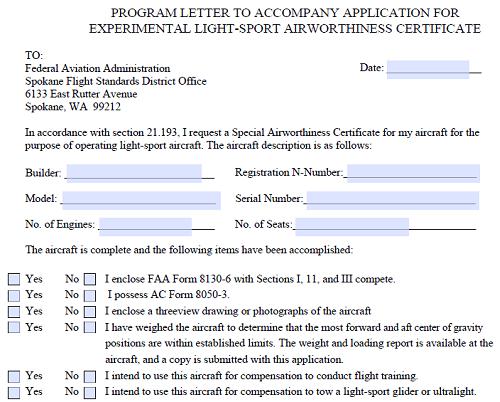

Program

Letter

You can ask for whatever Phase I flight test area

you want. I asked for a 25NM circle around the airport, and

had no trouble. I have also heard guys specify the corners of

the area they want, using airports for the corners. Download a Program Letter here.

(Adobe pdf file).

Picture

or 3-view drawing - You have to have

either a picture of your airplane, or the three view

drawings, on hand for this kit plane certification. Ask your inspector which he prefers.

Weight

and Balance – see my article on how

to do the Weight and Balance calculations.

Condition

Inspection – You can use whatever

inspection checklist you want. I looked on line and found

several checklists from other RV-8 builders.

Aircraft

Maintenance Records

Usually this is an airframe logbook and an

engine/prop

logbook. The following entry is required in the airframe

logbook for your final kit plane certification:

“I certify this aircraft has been inspected in

accordance with the scope and detail of Appendix D to Part 43 and has

been found to be in a condition for safe operation.”

Prepare Your

Aircraft

The inspector will be looking specifically for each of these items

to be correct before he'll sign off on your kit plane

certification.

N-Number

Most of us can get away with using the 3”

letters. You only have to use the 12” letters if your

cruising speed will be above 180 Knots CAS. There are very

specific requirements for the lettering. According to FAR

45.29, “Characters must be two-thirds as wide as they are high, except

the number "1", which must be one-sixth as wide as it is high, and the

letters "M" and "W" which may be as wide as they are high. Characters

must be formed by solid lines one-sixth as thick as the character is

high… The space between each character may not be less than one-fourth

of the character width.”

EXPERIMENTAL

According to FAR 4.23, “the operator shall also

display on that aircraft near each entrance to the cabin or cockpit, in

letters not less than 2 inches nor more than 6 inches in height, the

words "limited," "restricted," "experimental," or "provisional

airworthiness," as the case may be.”

Label

the Fuel Tanks

You should mark the tanks with capacity and min

fuel grade.

Passenger

Warning

You have to use these exact words, and they must

be in full view of all occupants.

“Passenger Warning – This aircraft is

amateur-built and does not

comply with federal safety regulations for standard aircraft.”

Data

Plate

FAR 45-11 and 45-13 require a “fireproof plate

with [builder’s name, model designation and serial number] marked on it

by etching, stamping, engraving, or other approved method of fireproof

marking. The identification plate for aircraft must be secured in such

a manner that it will not likely be defaced or removed during normal

service, or lost or destroyed in an accident… The aircraft

identification plate must be secured to the aircraft fuselage exterior

so that it is legible to a person on the ground, and must be either

adjacent to and aft of the rear-most entrance door or on the fuselage

surface near the tail surfaces.”

Make sure this data matches exactly the data on

your FAA form 8130-6.

Emergency

Locator Transmitter (ELT)

All fixed wing airplanes with more than one seat

have to have an ELT installed.

Paperwork

in the plane

This paperwork must be in the aircraft at all

times -- not just for the inspection, but the entire time you are

operating the aircraft. It's like the requirement to keep

registration and proof of insurance in your car. You can have

these documents in any safe location within the aircraft. I

have mine in a document protector behind the seat.

- FAA Form 8050-3, Aircraft Registration

Certificate

– The FAA will send you this after assigning you an N-number.

- Complete weight and balance paperwork – Talk to

your inspector to find out exactly what calculations he wants you to

make.

Cockpit

Markings

All controls, switches and knobs need

labels. For example:

- Ignition – On/Off

- Fuel selector – Left/Right/Off

- Airspeed indicator – White, red and green marks

Other

Prep

- Open all inspection panels/fairings

- Re-check all the flight controls and ensure

everything works properly

- Have your builder log and photos ready for

review

My Inspection

As I said before, the preparation was a lot harder

than the actual kit plane certification inspection. My DAR showed up and gave the airplane

the once over from 10 feet. He walked all the way around and

I think looked at the big picture. Then he moved closer and

looked at the workmanship of the airframe itself. He ran his

hand over a few of the rivet lines, then leaned into the cockpit and

looked back into the tail. I think he was looking at the back

sides of the rivets and probably at the edge distance too.

Then he moved every control surface to check full

range of motion and no binding. He spent a few more minutes

looking into the cockpit. I let him look without bothering

him, but I think he probably looked all the controls over.

I have an alternative engine installed, so he

didn’t spend a lot of time looking the engine over. He did

give it a look though to make sure there wasn’t anything glaringly

wrong.

He found four things that I needed to fix.

1. I had assumed the aileron pins wouldn’t slip

outboard because the bracket was in the way. But they had, so

I needed to crimp the outside edge of the hinge.

2.One nut on a brake line had a little leak, a

quarter turn fixed it on the spot.

3.The elevator control rod was bending at the

bellcrank when I went full left and down. This took a little

time fine adjusting the angle of the rod end.

4.The flap pushrods were not binding, but had no

slack and couldn’t wiggle at all when the flaps were

extended. It turned out that the weldment was pinching the

rod end when I tightened the bolt. A couple of washers

between the rod ends and the weldment fixed the problem.

He took some time to look through all the pictures

of the build, and glanced at my log book. Then we went in the

office and did the final kit plane certification paperwork.

Return

from Kit Plane

Certification to Experimental Aircraft Paperwork

Return

from Kit Plane

Certification to Kit

Plane Advice Home

|