Electric System Lessons Learned

or

What

I Would Do Different

I learned many electric system lessons as I installed

the various systems in my aircraft. Many of these ended up as

notes on how I would do things differently if I were starting again.

Perhaps these will give you some ideas for better ways to

build your airplane.

Wire

up

the tail before riveting the turtledeck

I didn’t have the luxury

of waiting

on the turtledeck until

after I had run the electrics. I

was

close to moving to Louisiana

and had a half-built fuselage. I

needed

to finish the turtledeck and the canopy to feel safe hauling it down

the

road. Most builders

will probably not

face this problem.

You can still accomplish

a lot of

building with the

turtledeck only clecoed on. The

ability

to remove the turtledeck will save you a lot of time and the pain of

crawling

into the back of the tail. With

the

turtledeck removed you can easily rig the entire elevator pushrod,

bellcrank

system. You can

also reach over the side

and drill the holes, run and clamp the conduit, and build and install

any

mechanical fixtures.

If I were able, I would

have done all

of the following

before riveting on the turtledeck:

- Built

and installed the longer

F-818C-L and R needed to hold the autopilot servo.

- Drilled

and primed all the

electrical holes

- Installed

the outside air

temperature (OAT) probe

- Built

and drilled the bracket for

the Dynon remote compass, but not installed it (I

think it would get in the way of crawling to the back to rivet, so

would save

it for later)

- Run

and clamped the conduit

- Pulled

the wires for the tail

lights, elevator trim, OAT probe, and remote compass

- Soldered

the d-sub for the remote

compass

- Drilled

and installed the static ports

Then after the turtledeck

was riveted

in place, I would

finish:

- Installing

the pitch servo on the F-818Cs

as I installed the F-635 elevator bellcrank assembly

- Installing

and connecting the

remote compass

- Installing

and connecting the

static lines

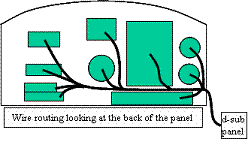

Wiring panel

I am happy with my

wiring, it all

works! But I think

if I was to do it again, I would

make a change to make removing the main panel easier.

At the top of the left gear box, I would

install a plug panel with several d-sub connectors like in the picture. The panel would have

socket savers mounted to

it, providing male on I am happy with my

wiring, it all

works! But I think

if I was to do it again, I would

make a change to make removing the main panel easier.

At the top of the left gear box, I would

install a plug panel with several d-sub connectors like in the picture. The panel would have

socket savers mounted to

it, providing male on  one side of the panel, and

female on the other. Then

all of the wire runs

to the airplane

would start there with a male fitting and go aft.

The wiring for the panel would start there

with a female fitting and go to the back of the instruments. I would run all the wires

from the

instruments into the center of the panel, then run the one large bundle

to the

left, then back to the d-sub panel. one side of the panel, and

female on the other. Then

all of the wire runs

to the airplane

would start there with a male fitting and go aft.

The wiring for the panel would start there

with a female fitting and go to the back of the instruments. I would run all the wires

from the

instruments into the center of the panel, then run the one large bundle

to the

left, then back to the d-sub panel.

I know this would add a

little

weight, but the ease of

maintenance provided would outweigh the penalty. It will also make

running the

wires easier. Measuring

the length of

the wire will be easier too because you will know exactly where to

start

measuring from at the panel end.

A quick look on the web

found everything

I would

need: socket

savers to go through the

panel, male and female connectors and their cases for the end of the

wire

bundles, nuts and screws. I

even found

a help document that has the size to cut the holes in the panel. I could connect

up my entire panel for about

$120. In fact, I

think the next time my

panel has to come off, I will do just that.

Use

multiple-wire

bundles

I ran individual strands

of wire for

everything. Next

time I would use multiple-wire bundles,

like Vans ES MSTS-WIRE. It

is the

six-wire bundle needed to connect the trim servos.

The autopilot, and possibly the intercom,

could

also be wired with multi-wire bundles.

Although this may

increase the parts

cost a little bit, it

will be a lot easier to install, and will weigh less.

You just need good measurements before you

order to ensure you get what you need, and not a lot extra.

Permanent Labeling

One of the biggest

electric system

lessons I learned was in wire labeling. I labeled my wires

with masking tape

while I was installing

them, and removed the tape as I crimped and fastened each wire. BIG MISTAKE! Now I have a bunch of

white wires that look

alike.

I would suggest

permanently marking

both ends of every

wire. If you use

multiple-wire bundles

with colored wires, you can label just the bundle, then list the colors

on your

electric diagram.

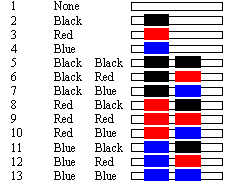

The technique I like the

best is the

use of different

colored shrinkwrap. A

single piece of

one color can be put on each end of a wire, or you can mix colors. For example, with just

three colors of

shrinkwrap, you can mark a 13 wire bundle like this:

Mark

the wires on your schematic to match

the shrinkwrap, and tracing electric wires later will be a lot easier.

Mounting the Radio Trays

I

mounted the back of the trays to the F-802NPP L.G. Box Upper Brace with

a screw. I thought I had located it where it would be easy to

install and remove, but it was harder than I

thought. I

initially thought I would be able to easily reach the top of the

radios, but that isn’t the case. I have to remove my GPS and

its

mount to get to the screw for the radios. I

mounted the back of the trays to the F-802NPP L.G. Box Upper Brace with

a screw. I thought I had located it where it would be easy to

install and remove, but it was harder than I

thought. I

initially thought I would be able to easily reach the top of the

radios, but that isn’t the case. I have to remove my GPS and

its

mount to get to the screw for the radios.  Otherwise,

with a lot

of difficulty, I can reach through the radio trays to get to the screw. Otherwise,

with a lot

of difficulty, I can reach through the radio trays to get to the screw.

The

next time I remove the instrument panel, I will change the

setup.

I will remove the small piece of angle aluminum I riveted to the top of

the radio trays, and will rivet it to the bottom of the

trays.  Then I will

screw or rivet a straight piece of aluminum to the back of

the F-802N that matches up to the angle. Then I can screw the

two

together from below the radio trays without effort. Then I will

screw or rivet a straight piece of aluminum to the back of

the F-802N that matches up to the angle. Then I can screw the

two

together from below the radio trays without effort.

Landing/Taxi

Lights

If I was starting a new project, I would check out

the new

Landing/Taxi/Wingtip combo lights.

Return

from Electric System

Lessons Learned to Electrical

Systems

Return from Electric Systems Lessons Learned

to Kit Plane Advice Home

|