|

Digitrak II Autopilot

This is specific advice on installation of the

Digitrak II Autopilot in a Vans RV-8. This could also prove

valuable to builders of other Vans kits or other aluminum kitplanes.

Mechanical

Installation

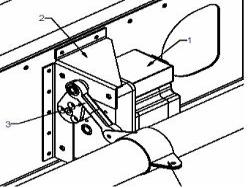

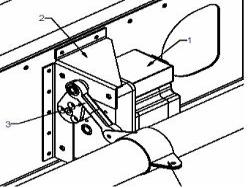

Installing

the

pitch trim went according to the plans. But the roll trim

drawing isn’t correct. It shows the bracket

backwards. This wasn’t a big deal. You can see in

the picture

how everything still fits. Installing

the

pitch trim went according to the plans. But the roll trim

drawing isn’t correct. It shows the bracket

backwards. This wasn’t a big deal. You can see in

the picture

how everything still fits.

The drawing showed how

long to make the pitch push rod. To be sure, I connected the

elevators, the F-841 push rod, and the F-635 elevator bellcrank to the

servo. Then I made sure it could travel from stop to stop

without reaching the limit of travel of the servo arm.

The

roll was a little harder. The drawing showed the push rod to

be only as long as the two ends. So I was assuming that was

the right length. I didn’t finish hooking it up until the

wings were mounted, and the ailerons fully installed and

rigged. Only then did I know the full travel of the WD-807

control column. Then I clamped the torque tube bracket to the

WD-807 with a side grip cleco and ensured I had full range of motion

and didn’t reach the limit of the servo arm. After I was

satisfied, I drilled the hole and used a blind rivet to hold the torque

tube bracket.

Wiring

I

started wiring the

autopilot at the bench. I had already measured, cut, and

marked the wires that needed to go into the d-sub connector.

Working in an upright position with good lighting is much easier than

on my back under the instrument panel (See Helpful

Hints for Soldering Terminals). After the panel end

of

the “bundle” was wired up, I threaded the other ends through the

bulkheads and conduit. See Use

multiple wire

bundles for what

I would have done differently.

Unfortunately the

smaller d-sub connectors don’t fit through the holes and

conduit. This means I had to wire them inside the fuselage.

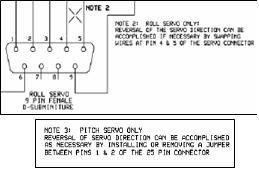

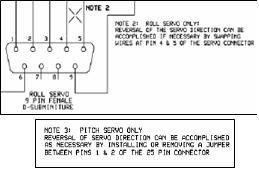

True

to form, I also

had to change the pins for the roll trim and add the jumper between

pins 1 and 2 for the pitch trim. According to the Digitrak

II Wiring Diagram Notes 1 and 2, if you need to reverse the direction

of the servos, you will have to make these changes. Murphy’s

law struck again, and I had to make both changes. True

to form, I also

had to change the pins for the roll trim and add the jumper between

pins 1 and 2 for the pitch trim. According to the Digitrak

II Wiring Diagram Notes 1 and 2, if you need to reverse the direction

of the servos, you will have to make these changes. Murphy’s

law struck again, and I had to make both changes.

If

your

servo installation looks the same as mine in these pictures, you should

start with main unit pin 21 to roll pin 4 and main unit pin 20 to roll

pin 5. You will also need to jump pins 1 and 2 on the main

unit.

Testing

I

tested the electric

connections by hooking

up the battery from my truck to power the unit. Don’t hook up

a trickle charger as it might ruin your electronics. The

small 3 amp power supply I had wasn’t enough to run the servos, so I

used the battery.

It was easy to check

the roll, I

just set the unit to HDG Hold, then turned the knob. The

autopilot tried to turn the plane to intercept the new heading.

The

pitch trim was a little harder because I had already mounted the

autopilot unit into my instrument panel and didn’t want to pull it

out. So I put the Digitrak II into ALT Hold mode and raised

and lowered the tail. This was enough to raise the unit

itself, causing it to move the elevators. I would suggest

keeping the unit out, where you can easily move it up and down to do

this test.

Return

from Autopilot

to Electrical Systems

Return from Autopilot to Kit Plane Advice Home

|

Installing

the

pitch trim went according to the plans. But the roll trim

drawing isn’t correct. It shows the bracket

backwards. This wasn’t a big deal. You can see in

the picture

how everything still fits.

Installing

the

pitch trim went according to the plans. But the roll trim

drawing isn’t correct. It shows the bracket

backwards. This wasn’t a big deal. You can see in

the picture

how everything still fits.

True

to form, I also

had to change the pins for the roll trim and add the jumper between

pins 1 and 2 for the pitch trim. According to the Digitrak

II Wiring Diagram Notes 1 and 2, if you need to reverse the direction

of the servos, you will have to make these changes. Murphy’s

law struck again, and I had to make both changes.

True

to form, I also

had to change the pins for the roll trim and add the jumper between

pins 1 and 2 for the pitch trim. According to the Digitrak

II Wiring Diagram Notes 1 and 2, if you need to reverse the direction

of the servos, you will have to make these changes. Murphy’s

law struck again, and I had to make both changes.